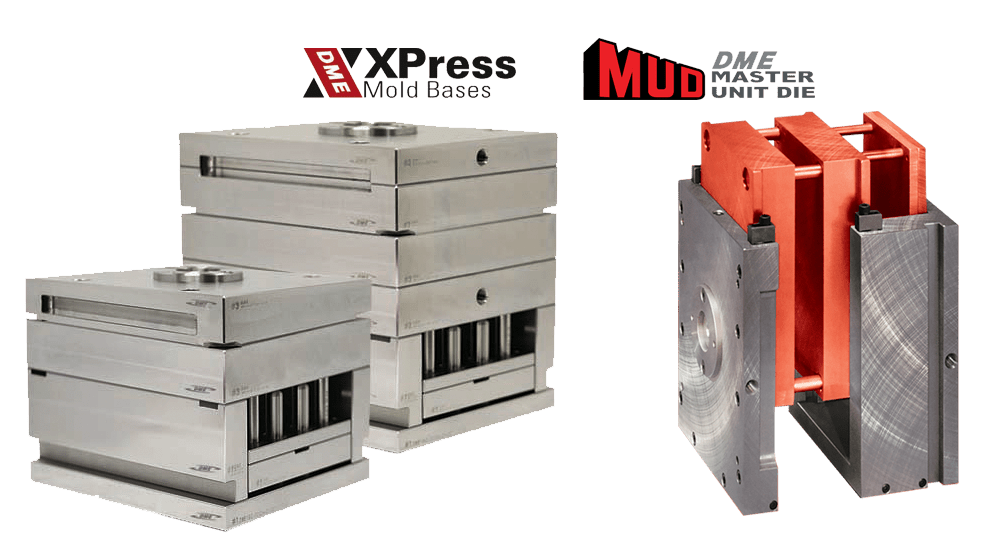

The availability of “off-the-shelf” total mold solutions, all available on the DME eSTORE, is allowing customers to manufacture the tooling needed at record speeds.

“The DME XPress® mold bases and, our Quick-Change MUD® systems have been configured and ordered online and have literally been flying off the shelf” stated Peter Smith, President DME.

DME was assigned the status of being “essential” in the supply of “critical infrastructure” such as healthcare, pharmaceutical and food supply required during the current COVID-19 emergency and has responded accordingly. Production hours at both the DME Greenville, Michigan and Windsor, Ontario mold base manufacturing plants have been extended to keep up with demand.

“The North American mold making industry has responded magnificently to the challenge. Our customers, some of whom have never made healthcare products before, have used their creativity to develop new products and new tooling in record time. This is typical of the “can-do” attitude of our Industry” Smith further commented.

Mayer Tool and Engineering located in Sturgis, Michigan is just one great example of the partnership DME has enjoyed with its customers to successfully make the products needed by the healthcare industry. “DME has been great. When we were asked to make respirator masks and face shields for doctors and nurses, we immediately turned to DME and Spectrum Design Group Inc for assistance. DME worked with us and delivered everything we needed in record time. We have shipped our tooling and its now in production making products for the healthcare community” stated Caralee Mayer, Co-Owner.

“As an Industry we have responded magnificently so far, but the fight is not over. We will continue to support our customers through this period while ensuring employees are safe” concluded Smith.

We would like to thank all of DME’s customers and employees for their great work at this crucial time in our nation’s history. Together we will beat the invisible enemy.

#STAYSAFETOGETHER

Recent Comments